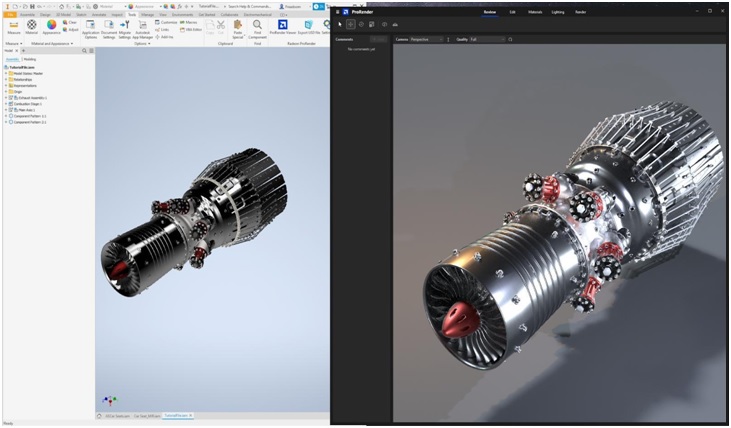

Inventor – How to Use Inventor to Create Mechanical and Structural Designs

Inventor is a computer aided design application that allows you to create designs, document them, and then use them for simulation, motion simulation, and 3D mechanical design. The software is easy to learn and provides you with a wide range of features for building, drawing, and analyzing your designs.

Stress analysis

Inventor Stress Analysis is a specialized tool for calculating structural FEA. The FEA results are displayed in a graphic area, and can be used to ensure that your designs will perform as intended under expected use.

The FEA process usually employs high-performance computer systems. Finite element techniques help avoid remeshing when analyzing growing cracks. In addition, they allow for analysis of multidirectional stresses. This is especially useful for parts that are subject to fatigue failure.

The FEA process is also used to evaluate structural loading conditions. The method usually includes modal analysis, which is defined as a dynamic force. These methods are particularly useful for analysis of orthotropic composites.

The Autodesk Inventor Stress Analysis feature is located in the ENVIRONMENTS tab of the design application. You can set up the simulation environment for static or modal analysis, or use a combination of both. The feature allows for unlimited settings, and you can import forces from a dynamic simulation. You can also view the full report and display the stress loads in different factors.

The Stress Analysis Settings dialog box contains a Parametric Table, which provides guidance on the simulation process. To start the process, click the Create Study button. The resulting dialog box will allow you to select a model, enter input forces, and specify the boundary conditions.

Depending on the complexity of the assembly, you may not be able to obtain all the information from an analysis of just one part. It is important to consider the material properties of the components. These properties can be determined experimentally, or with uniaxial stress tests. You can then combine the parts to see how they perform. This will be helpful in designing the best possible design.

A suitable analysis technique will provide reliable results for the boundary conditions, as well as the magnitude and distribution of strains. This will be crucial in predicting the strength of the structure. Whether it is an adhesive joint, a welded joint, or a printed circuit board, it is important to have a thorough stress analysis.

The Autodesk Inventor stress analysis feature can help to ensure that your designs will be capable of performing as expected. In addition, it can reduce the consumption of machine labor, materials, and human labor.

Motion simulation

Using a motion simulation software product can help you build a better product. By understanding the mechanics of your design you can make improvements before cutting into the actual material. With a tool like Dynamic Designer trapped you can answer questions about how your designs perform before you start building.

This software package is designed to be easy to use and to provide you with the data you need to build a better product. It can simulate the motion of a moving assembly in 3D. It can also be used to identify potential problems in your design before you spend time and money putting together the actual physical assembly. This will allow you to more efficiently work with Inventor.

The Inventor Lite and Professional versions have motion simulation capabilities. This is a powerful tool that can be used to calculate the maximum number of stress values for an assembly. In some cases the results might not converge. But in general the software will calculate the best results for your design.

The software is capable of simulating the motion of multiple joints in a crane assembly. This includes both radial and translatory movement. This feature is especially useful in calculating the relative motion of various assembly components. It is also possible to animate CAD assemblies with SolidInvent3D.

There are other tools to help you determine the kinematics and dynamics of a moving assembly. The software will help you create a working virtual prototype, but only if you know how to use it. This article will help you get started. There are three steps in preparing a virtual prototype for testing. The first step involves creating a digital geometric model of your vehicle. Once you have done that, the next step is to test the model in the dynamic simulation environment. The results will be analyzed and conclusions drawn. The results can then be used to optimize your design. This will save you both time and money.

The process can be a bit daunting, but the results can be extremely valuable. In the end, you will have a better understanding of your design and you can begin working more efficiently with Autodesk Inventor.

AutoCAD vs Inventor

Inventor and AutoCAD are two different CAD software programs that allow users to create drawings and models. Despite the similarities in these programs, they are very different and have unique purposes.

Inventor is a parametric CAD application, which means it creates precise 3D models. This helps manufacturers to design and test prototypes for their products. In addition, it also has the ability to simulate materials and motion. It is best suited for mechanical and engineering designs.

The interface for Inventor is designed for ease of use. It has a more intuitive workflow than AutoCAD. It has a contextual menu, which is accessible by right-clicking. This makes it easier to find the tools you need.

With Inventor, you can simulate the motion of robotic machines and test the movement of material. It is also useful for resizing 3D models. In addition, Inventor has contact solvers and advanced tools for assembly. The model can be exported to a 2D DWG file. It is also compatible with IDW and IPT.

It is more versatile than AutoCAD. For instance, you can draw the outline of a house or a car. You can set constraints for the parts to fit together. You can also create moving lego models or car engines.

Unlike AutoCAD, Inventor does not have command line. However, you can import and export your files from AutoCAD. You can also export your 3D model to a 2D DWG file.

Both programs have similar functions, but Inventor is more intuitive and offers faster results. Moreover, Inventor is oriented towards mechanical and electro-mechanical design, and it is easier to use for these types of designs.

On the other hand, AutoCAD has a more generic domain. It is more suited for mechanical and electrical design, as well as for civil and building architecture design. It is also very good for reviewing prototypes and creating accurate engineering drawings. The cost of upgrading to the latest version of the software is included in the annual fee. It also has a 30-day trial version.

Both AutoCAD and Inventor are popular CAD software programs. They are used by engineers, architects, cartographers, and designers.