Here Is What You Need To Know About Impact Testing Machines

The impact test process is used to study various characteristics of the material. These include toughness, toughness, flexibility, and strength. It involves the sudden application of a load to the sample to determine its impact value. The impact testing machine will capture the material’s impact value, which varies with temperature, size, and the amount of plastic deformation it can absorb.

This is why it is important to determine whether a material is strong or brittle. Temperature can cause a positively correlated impact value change. This means that, generally, the lower the temperature, the lower the impact energy of the material, as the temperature increases, the impact energy of the material increases. In such cases, the size is a factor that affects the results of the cantilever beam impact tester which leads to a series of defects in the material.

These can be used as pressure boosters to reduce impact energy. The toughness of the material indicates its ability to absorb energy during deformation. Materials with low toughness usually can only withstand small plastic deformations.

The main purpose of using the impact testing machine is to determine the ability of a material to absorb energy during a collision. This energy can be used to determine the toughness, impact strength, fracture resistance, impact resistance, or fracture resistance of the material, according to the test carried out and the characteristics to be determined. These values are important as they help select materials for use in applications that require the material to withstand very fast loading processes (such as in-car crashes).

Different types of tests conducted on Impact Testing Machine

IZOD Impact Tester

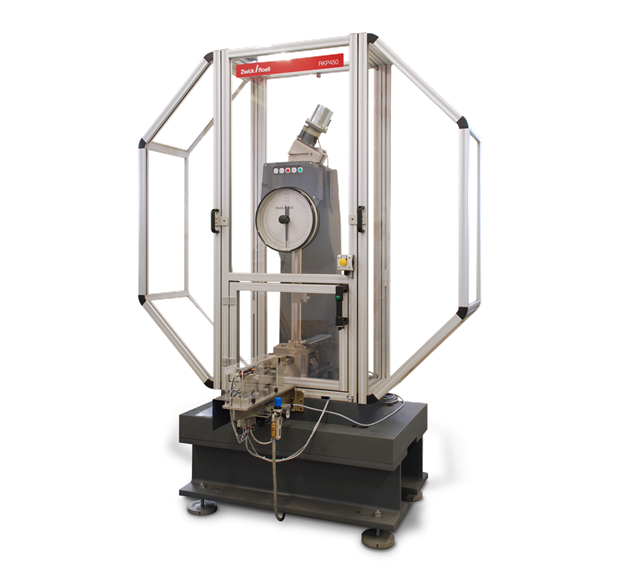

The IZOD impact testing machine is also called a pendulum impact testing machine. The impact resistance of the sample is measured by different standard test settings. The test consists of a pendulum or pendulum, a support frame, and a ninety-degree angle measurement system that measures absorbed energy. Notched Impact in the Test determines the behavior of the material sample at a higher strain rate. Measure the height of the pendulum rise after impact to determine the impact energy absorbed by the material sample until it breaks.

During the test, the specimen is to be supported as a cantilevered beam. The firing pin should be close to the hammer, and the locking position should be set to ninety degrees.

After placing the metal sample in the holder with the notch forward in the direction of the striker and releasing the hammer, the pointer will display the energy consumed by the sample as a function of its breakdown.

This test mode involves high strain rate testing to measure the impact value of certain samples. After being put through the impact testing machine, these specimens have standard dimensions and can be found in various industry standards.

Charpy Impact Tester

Charpy impact testing machine is used on machines that are capable of measuring less than 1 foot-pound to 300 foot-pounds at temperatures from negative 320 ° F to 2000 ° F. This is a high strain rate test in which a notched sample is struck with a weight-controlled pendulum that swings from a set height.

This test measures the impact energy absorbed by the sample when struck by a pendulum. It is considered a good metal impact testing machine. It shows whether the sample can be classified as ductile or brittle, especially ferritic steel. According to the results, brittle metals absorb a small amount of energy. On the other hand, strong ductile metals absorb a lot of energy.

Final Words

Therefore, this was a small guide to impact testing machines and the different tests conducted to determine the strength of the metals.